Rotogravure Printing

Rotogravure printing is a high-volume printing process employing an ink transfer mechanism. Each gravure cylinder is housed in separate housing stations. The web or substrate is transported by rollers from station to station. After each color is printed, the web passes through a dryer where the solvent-based ink is made to evaporate.

We specialize in printing on paper substrates with a width up to 1000mm and use an Electro Static Assist (ESA) to eliminate any white dots, also known as dot skip, in the printing quality. Any design can be printed on the substrate using a combination of different colors.

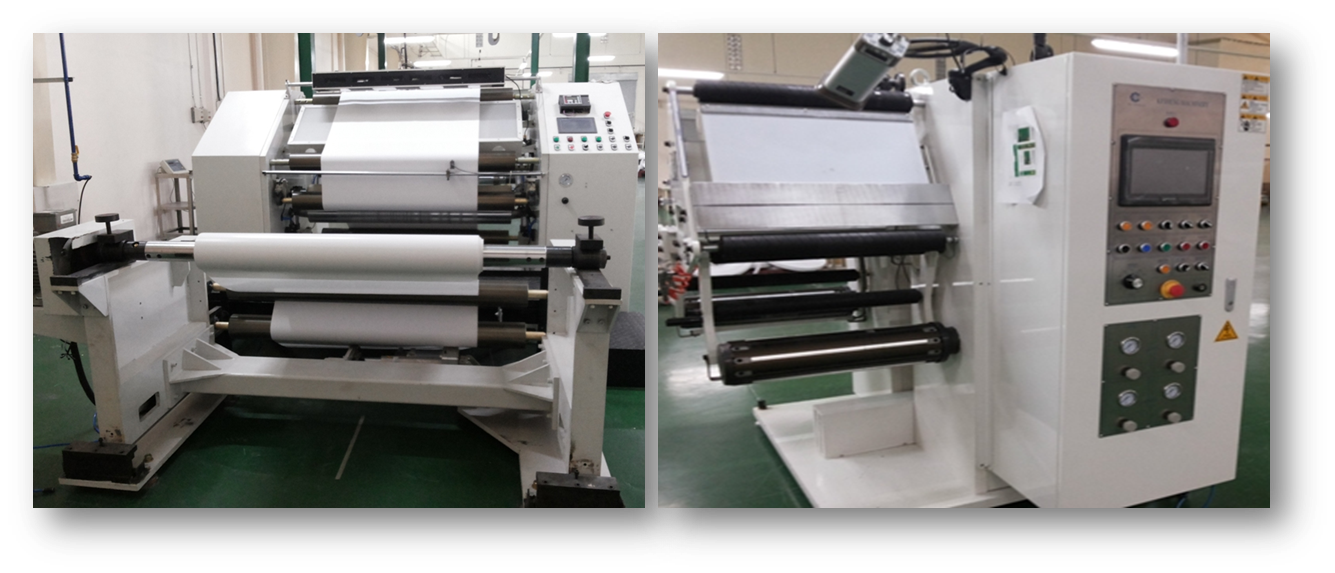

Slitting and Rewinding

The slitting and rewinding process is very critical as it is usually the last process before product deliveries to the customer for roll products. As such, we ensure that every roll is thoroughly checked and sorted so that the products are free from any defects.

Sheeting and Cutting

These sheeting and cutting machines are specifically used for the paper products where the customer requires the end product to be in sheet form instead of in roll form. The rotogravure print is first cut into big sheets from the roll form by use of the sheeting machine and then it is cut to the final required size by the guillotine and corner cut machines.

Spot Checking & Quality Checking

With the use of a Jumbo Rewinder and a Doctoring machine, the printed rolls can be quality checked to ensure that there are no printing defects on the end product especially when the operators have initially tagged the printed rolls for checking.